CUSTOMISED MACHINES

If our standard machine tools or tables doesn’t meet your specifications, we develop for you a custom machine suited to your criteria whilst complying with current safety standards (Directive 2006/42/EC).

With decades of expertise, Roty & Fils offers custom-made industrial tables and machine tools. Our team of highly qualified technicians and engineers works tirelessly to design and produce solutions that precisely meet your requirements. Each project represents a challenge that we tackle with professionalism, guaranteeing reliable, high-performance, and durable solutions.

As designers and manufacturers, we provide you with customized solutions. Our R&D department specializes in developing bespoke solutions, created by an experienced team of metalworkers, cable technicians, programmers, and assemblers.

Contact us to discuss your custom industrial project.

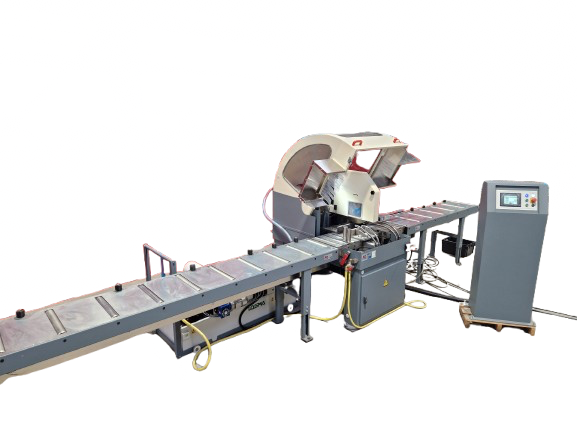

RADIALU CROSS-CUTTING MACHINE

Cutting long aluminium profiles

Find out more

This machine tool was designed by our design office using our french expertise to meet our customer’s specific requirements.

This custom-built cut-off machine is designed for straight and angular cutting of aluminium profiles. An infeed and outfeed table system can be added as required.

DRILLING – SAWING COMBINATION

Customised device for drilling, sawing and milling all types of profiles

Find out more

This combined drilling – sawing unit was carefully designed in its entirety by our design office to meet our customer’s satisfaction.

This machine reflects our French expertise, with its wide range of production options : drilling, tapping, milling.

This custom-built machine is equipped with a complete safety system to ensure operator safety. It is accompanied by a prouction input and output device to increase overall productivity.

manual dry cutting machine with bonnet

TMS 525

Cutting any type of steel section using an oscillation system

Find out more

This TMS 525 dry cutting-off machine with bonnet is capable of cutting any type of steel section : round, tube, rectangular tube or square tube. This machine offers cutting performance even on solid sections.

This complete system reflects our expertise in machine tools, with a focus on safety, productivity and customisation.

Our TMS cross cut saw can be coupled with one of our conveyors equipped with digital stops (VISIONIC and TYRObut range) to increase your productivity.

TSA LAB 525

Semi-automatic grinding wheel saw – concentric vice

Find out more

SAWING MACHINE – GRINDING WHEEL Ø508/406 MM – 18.5 KW MOTOR

MAIN FEATURES

Motorization & Drive

-

Motor: 18.5 kW (25 HP) – 3000 RPM – Three-phase 400 V

-

Cutting speed: 60 m/s

-

Compatible with Ø 508 mm or Ø 406 mm grinding wheels – Bore 25.4 mm

-

Automatic downfeed

-

Automatic oscillation via gearmotor

Structure & Safety

-

Welded and powder-coated sheet metal base

-

Full enclosure with electrical safety interlock

-

Automatic depth stop (activates at end of cut – measures and compensates for wheel wear)

-

Working height: 920 mm

Clamping & Workholding

-

Two pneumatic vises

-

Large-capacity clamping table

-

Set of spacers for small profile clamping

Compliance

-

Machine compliant with current CE regulations

AVAILABLE OPTIONS

-

Mist eliminator

-

Media roll filter (optional handling cart)

-

Roller conveyor junction tables

-

Concentric pneumatic vise

-

Peripheral work tables

-

Manual or automatic stop

Mini roty

Laboratory chainsaw

Find out more

This cutting machine for steel guide rails is designed to provide safety, performance, and ease of use.

Thanks to its dry-cutting disc rotating at 40 m/s and T5 belt transmission, it ensures fast and efficient cutting.

This system offers several key advantages:

-

Low-inertia disc allowing a complete stop in less than 3 seconds for maximum safety,

-

Permanent protective cover, ensuring the disc is never exposed to the operator,

-

Double safety system: mechanical table lock via screw and electrical interlock via switch.

This all-in-one solution reflects our expertise in cutting machines, with special attention to user safety, productivity, and customization.

Optional features include:

-

Miniature graduated hole reworking kit

-

Sheet metal table (1000 x 200 mm)

-

Guidal system with miniature contact point

PROTO LABO CHAINSAW

Machine for cutting cable

Find out more

Machine designed for cutting MI cable in 304L stainless steel, 316 stainless steel, and Inconel.

Cutting

– Disc rotation speed: 26 m/s

– T5 belt transmission

Key machine features:

– Low-inertia disc (complete stop in less than 3 seconds)

– Double protective layer on the vise: glass shield + PETG screen

– Double safety system: mechanical table lock (screw) and electrical interlock (safety switch)

– Low translation resistance of the vise (brass key and rail system)

INCONEL TUBE CUTTING MACHINE

Special saw bench

Find out more

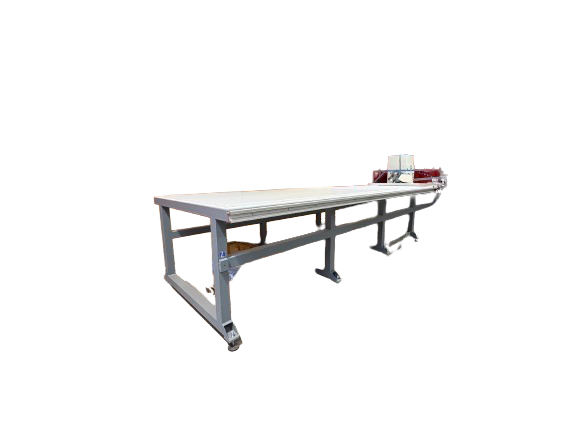

CUT-TO-LENGTH TABLE WITH FEED CARRIAGE – SPECIAL SAWING BENCH FOR STAINLESS STEEL PINS

TABLE FEATURES

The table is designed with a powder-coated, welded structure, ensuring strength and durability over time.

It has a working stroke of 5000 mm and a working width of 1500 mm, suitable for long and wide pins.

Table top secured to the table by screws

Longitudinal and transverse rulers for precise pin positioning

Table top and rulers made of HDPE material (strong and smooth-running)

Integrated drawer on the right side for storage or retrieval

MANUAL FEED CARRIAGE

The carriage allows for smooth and precise movement, while ensuring safe and reliable use. Manual adjustment with automatic backlash adjustment (rack/pinion)

Precision roller guidance on a chrome-plated axle

Quick release via indexable handle

Aluminum structure (80×40 profile) with support roller at the end

Clamping clamps mounted on the profile to hold the pins

Digital display: direct reading to 0.1 mm, 5-digit LCD screen (8 mm)

Floating zero, internal memory with battery backup

Battery operated, battery life of approximately 1 year, no connection required

CONDITIONS OF USE

The device is specifically designed for cutting stainless steel pins, within the following limits:

Diameter: 6 to 20 mm

Thickness: 1 to 2.5 mm

Length: 2400 to 4300 mm

(Minimum cuttable length: 295 mm)

Width: 70 to 1000 mm

DRILLING CENTRE

CP 220 – 2 heads

Drilling, tapping and routing device adaptable to all types of profiles

Find out more

The CP 220 2-head drilling centre is a customised numerically controlled machine tool. It is ideal for producing finished parts from bar stock.

This multifunctional drilling centre can perform multiple operations : drilling, tapping, routing and, as an option, flow-drilling. This device is suitable for machining all types of steel profiles along the X and Y axes (with the possibility of machining plastic profiles on request).

Depending on your production rates and the width of your bars and profiles, we can offer a device with one or two heads, with a vice width of 220 mm or 420 mm for high-precision work.

Contact us to discuss your customised industrial machine project together !

With ROTY et fils, everything becomes possible.

I NEED SOME CHANGES ON A machine

Located in Saint-Malo, Roty & Fils occupies a 1200 m2 production site with a team of about twenty people.

Our Design Department works in close collaboration with our sales staff to develop, improve and market a varied range of saws, cutting machines and combined drilling + sawing machines for aluminium, steel and other materials.

The experience and know-how of Roty & Fils and our commitment to quality and innovation are your best guarantee to find the solution for your cutting, drilling, trimming operations, etc.